2024-11-15

Xinhua News Agency, Shanghai, June 11th (Reporter Wu Yu) The “19th China International Mould Technology and Equipment Exhibition & 2019 Shanghai International Automobile Mould and Forming Technology Equipment Exhibition”, which opened in Shanghai on the 11th, sent out information: China’s mold consumption The volume reached 255.5 billion yuan in 2018, accounting for about one-third of the world’s mold consumption, and the mold output value also accounted for more than one-third of the world’s total mold output value.According to statistics from the China Mould Industry Association, in 2018, China’s mold exports were US$6.085 billion, an increase of 10.8% over the previous year, accounting for a quarter of the total global mold exports. The exports spanned about 200 countries and regions around the world, and the top five exports The markets are the United States, Germany, Hong Kong, Japan, and Mexico; mold imports are US$2.14 billion, up 4.3% year-on-year, accounting for one-eighth of the world’s total mold imports. The top five import markets are Japan, South Korea, and Germany , Taiwan and China.The mold is known as the “mother of industry”. According to the research of the China Mould Industry Association, the consumption of 255.5 billion yuan of China’s mold in 2018 can support 28 trillion yuan of industrial manufactured products nationwide. It is an important part of “Made in China” and plays a role as a “big country” To the role of “behind-the-scenes hero” that changes people’s lives. Taking the automobile industry as an example, the dependency of molds for automobile manufacturing has exceeded 90%, and more than 95% of the mold enterprises in the country involve automobile molds.According to statistics, in recent years, Chinese mold companies have accelerated their “going global” and completed more than 20 related mergers and acquisitions, with a transaction value of nearly 7 billion US dollars. The main mergers and acquisitions are in the direction of mold intelligence, electrification and light weight

2024-11-15

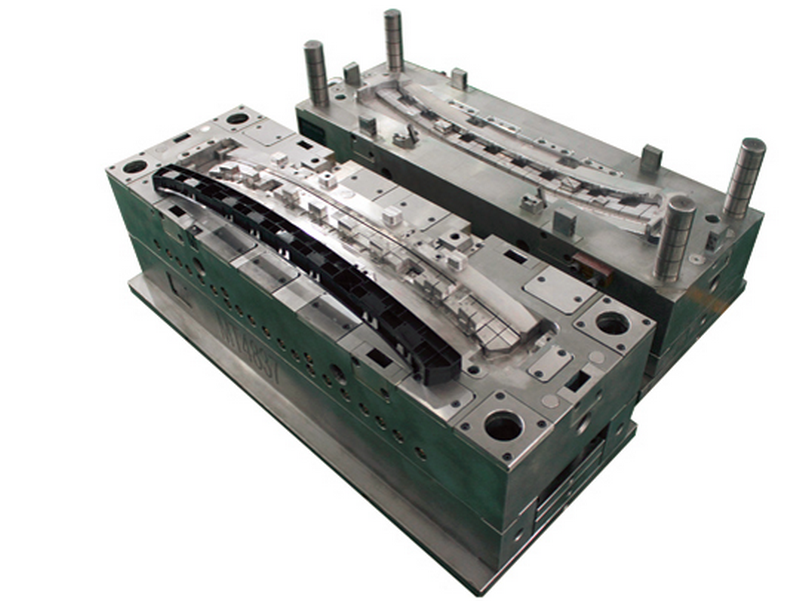

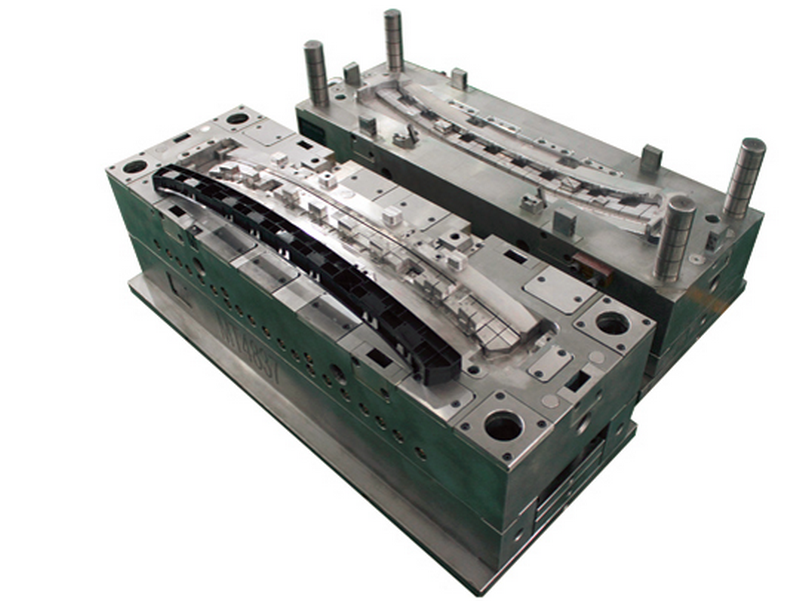

Most of the die castings are made from non-ferrous metals,such as Zinc, Aluminium, Magnesium and so on.Alumium alloy Die casting mold is an Alumium alloy casting process that by forcing molten aluminum under high pressure into a harden mold cavity blocks.It depends on the type of the raw material of die casting parts, we could choose a hot or a cold chamber machine to use.The mold material for die casting mold will be choosen by your request mold life :1.1730,P20,8407,2344,H13.Heat treatment of steel :Harden,Nitrition,QuenchAlumium Alloy part Material: ADC12(which is common material), AlSi12,ADC10,A380,A360,A413Magnesium Alloy part Material: AZ91D,AM60B,AM50A,AS41BSurface treatment can be made by machining,polishing,oxidation or painting.The ProcessThe die casting die or mold is a closed vessel into which molten metal is injected under high pressure and temperature, then rapidly cooled until the solidified part is sufficiently rigid to permit ejection from the mold.ToolingDies, or die casting tooling, are made of alloy tool steels in at least two sections, the fixed half (cover half) and the moving half (ejector die half), to permit removal of the castings. The dies also may have moveable slides, cores or other sections to produce holes, threads and other desired shapes in the casting. Making the MoldThe two die halves run in a die casting machine that is operated at the required temperatures and pressures to produce a quality part to net-shape or near-net-shape customer specifications. When the die casting machine closes, the two die halves are locked and held together by the machine’s pressure. The surface where the ejector and the fixed halves of the die meet and lock is referred to as the “die parting line”. The total projected surface area of the part being cast, measured at the die parting line, governs the clamping force of the machine.For longevity of operation in this environment the die casting die must be built from high-quality tool steel of exacting specifications, heat-treated to the required hardness and structure ( Guidelines from NADCA exist for this reason), with dimensions of the die and cavity machined to exacting specifications.The customer’s product design requirements directly affect the size, type, features, and cost of the required tooling. The items involved in the tooling decision include the number of cavities, number of core or slide requirements, weight of the die, machining, finish requirements, polishing and plating to name just a few.News:Household Mold MakersAluminum Alloy PartsThread Mould2 Color Overmolding PartsAutomotive Mould MakingVehicle Mould