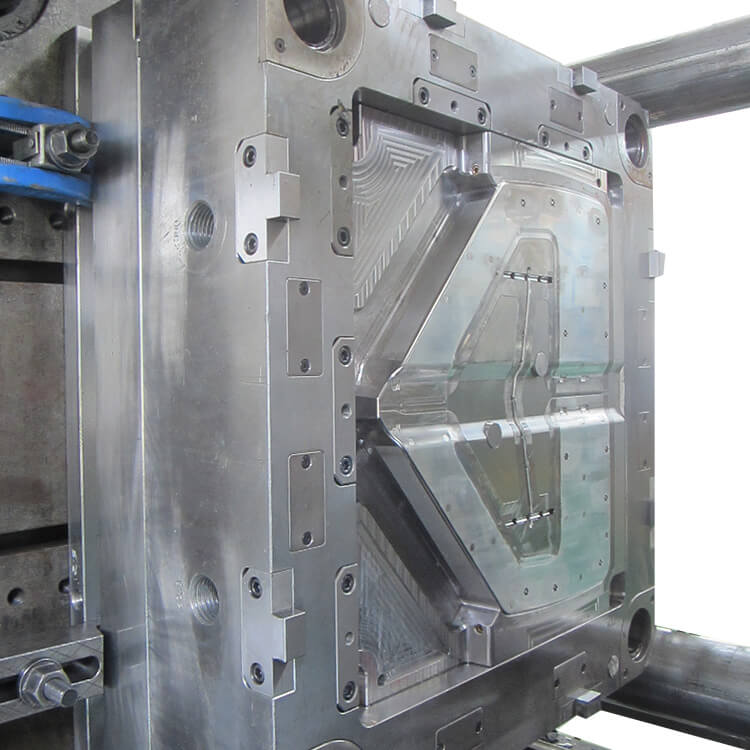

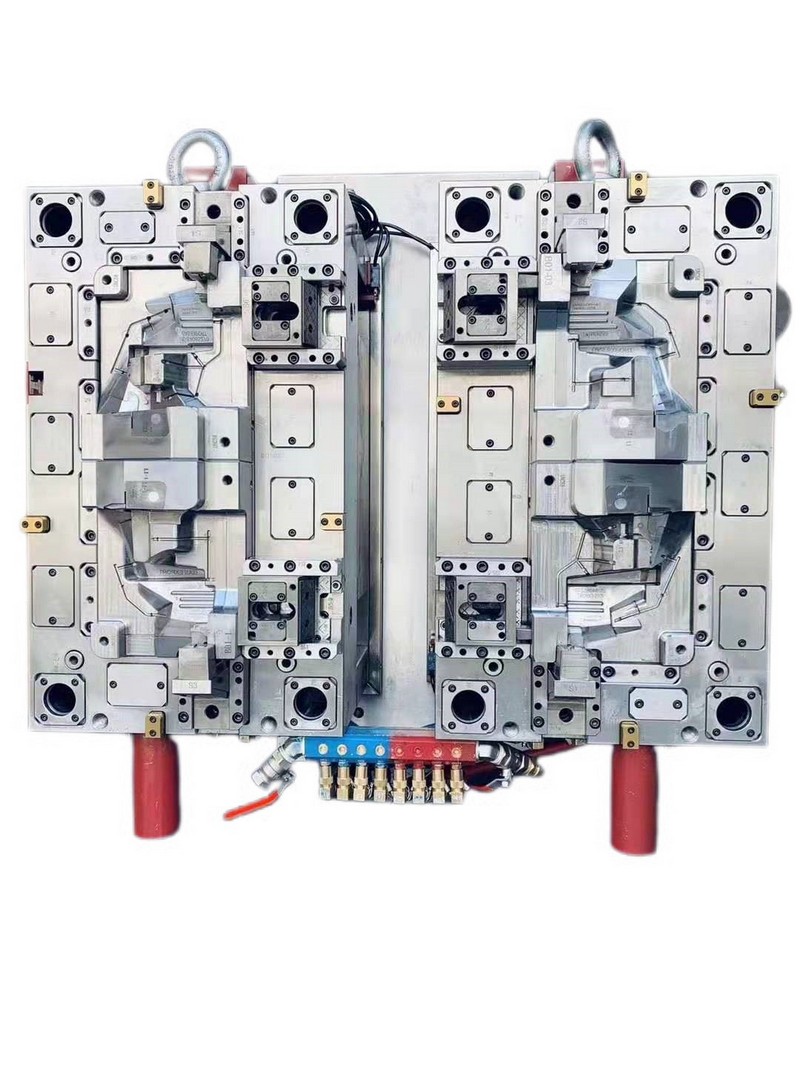

Model Number: TE02-021

Product Name: Auto Door

Brand Name: TTM

Mould Type: Plastic Injection Mould

Mould Base: S50

Mould Material: 2738

Mould Cavity: 1

Mould Life: 300,00 shots

Mould Standard: DME

Mould Size: 1380* 1350* 950

Plastic Parts Material: PA6

Lead Time: 7 weeks

| Brand | TTM |

| Mould Base | LKM, HASCO, DME, C50 standard mould base |

| Mould Material | H13, 1.2344, 1.2738, P20, 45#, etc., according to customers’ requirement. |

| Mould Standard | HASCO, DME, MISUMI, LKM, etc. |

| Product Material | ABS, PP, PC, PA, PA66, POM, etc. |

| Runner | Cold/Hot Runner |

| Gate Type | Side gate, sub gate, pin point gate, edge gate, etc. |

| Mould Size(min) | 150*150mm |

| Mould Size(max) | 1600*1200mm |

| Mould Weight | 50~15,000 kg |

| Injection Machine Type | 80~1500ton |

| Certification | ISO9001:2015 |

| Lead Time | 3~6weeks according to the product |

Talent Mould is specialized in manufacturing mould and precision parts, mould types include plastic and alloy mould, HASCO/DME standard mould, hot runner mould, double injection mould, etc., mostly used for automotive, industry, medical device, electronics, household and so on.

| Business Type | Manufacturer |

|

Advantage |

1. Equipment: Well-Equipped Facilities, And Most Of Them Imported From Abroad With High Precision.

2. Communication: Response Within 12 Hours ,And Great Technical Support Over 10 Engineers. 3. Experience: Over 10 Years Experience Working In Machining/Molding Line. 4. Quality: 100% Inspected, And Replacement Free Of Charges If Any Quality Problem From My Company. 5. ONE-Stop Service From Engineering- Prototyping- Production- Post Processing- Assembly- Packing. |

| Application | Automobile, Machinery, Automation, Electronics, Medical, Construction And Other Industrial Uses. |

It will take about 2-5 days for us to make 3D mould design , it will depend on how many sets of molds and how complexity of the mold.

If customer confirmed our 3D design, we ‘ll make 2D drawing with the BOM for our customer to check all of components steel material specification .

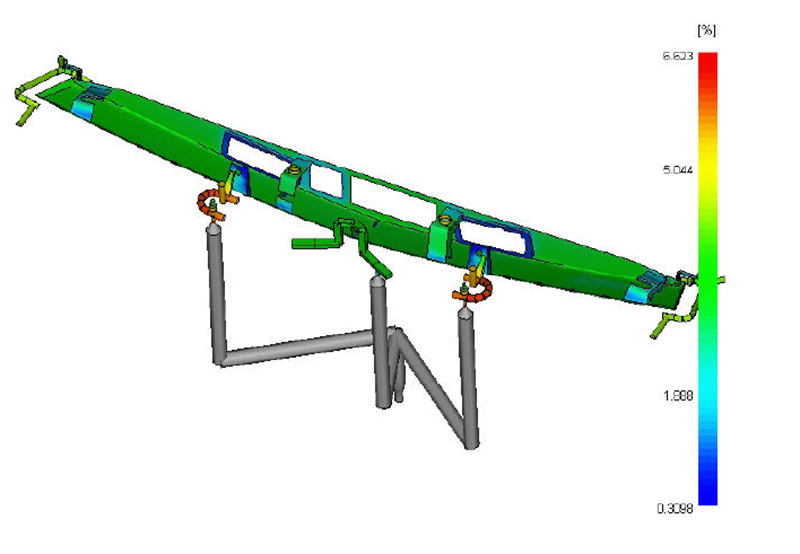

If the part is complexity , or the filling speed is hard to confirm, we could offer the mold analysis report to customer .

Our project manager having the following tasks / responsibilities:

● Project planning, reporting, change management and customer-interface organize and manage design & production reviews, try-outs with delivery of samples , final approval and mould delivery.

● Progress and status reports are issued each week including photos.

● Communication is done in English with marketing dept.

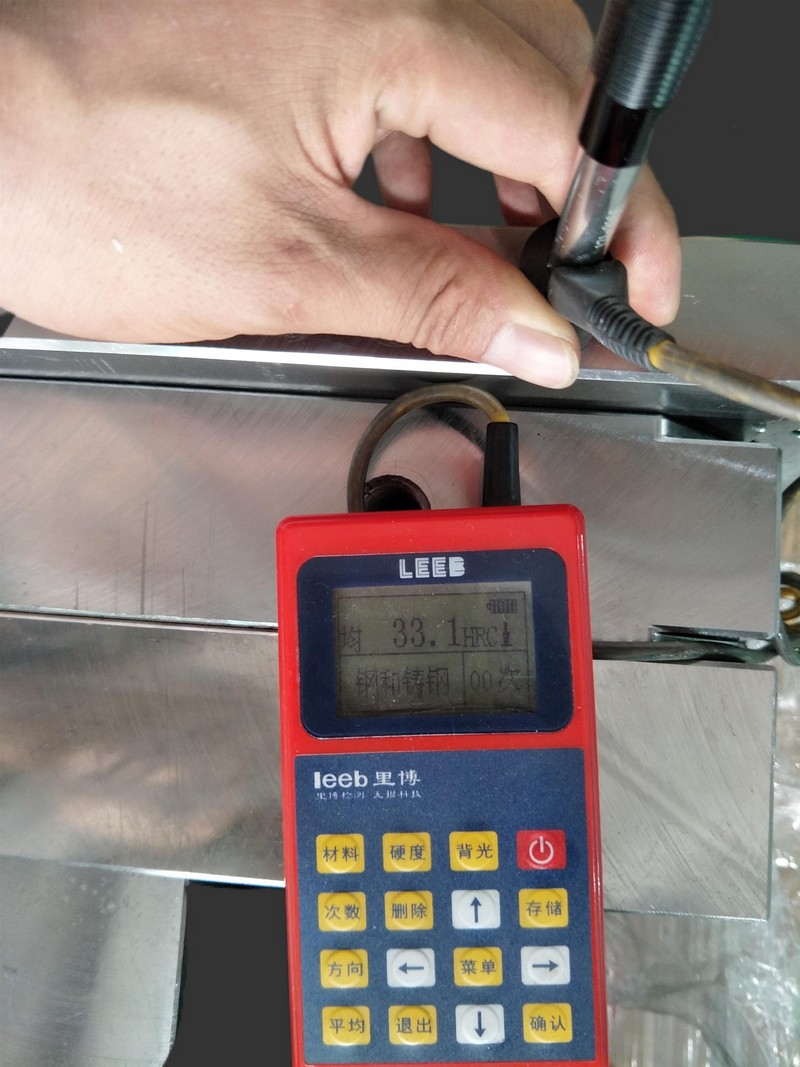

To be always able to deliver high quality mould an plastic products to our customers, the highest level of quality assurance is essential for us .

This starts with the contract review over the entire project cycle and ends with the shipping process.

We have therefore implemented a Quality Management System according to ISO 9001:2015 allowing for continuous improvement of our processes.