Company Profile

Established in 2008, Talent Technology Mould Co., Ltd is specializing in the area of engineering, developing and producing of injection moulds and die-cast moulds.

We supply molds for many different industries such as automotive, medical, industry, intelligent housing device, home appliances, commercial electronics, etc. Mould types include plastic and alloy mould, HASCO/DME standard mould, hot runner mold, double injection mold, etc.

TTM standard runs under ISO9001: 2015 quality management system. We focus on customer demands and regard quality as the foundation for our long-term stable development, setting up independent quality departments for mould manufacturing and injection molding. We sincerely hope we can cooperate with you to reach the goal of win-win cooperation

Our Factory

Talent now is relocated in a 2000 square meters factory with 60 staff in which includes 3 English-speaking project engineers, 6 design engineers and 30 mould makers. Consistent investment for new and better machines has enhanced our capability and will greatly increase our advantages in the market.

Main Equipments:

● 8 sets of CNC machine,

● 8 sets of EDM machine,

● 1 set of Gun drilling machine

● 1 set of CMM Inspection Machine

● Grinding machines

● Lathing machines

● 2 sets of injection machine

Capabilities

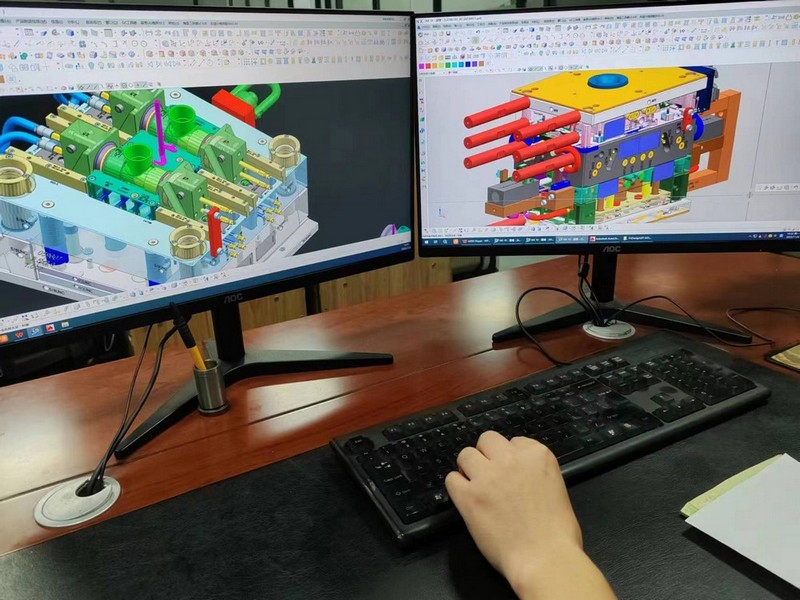

• Design & Engineering

• Product Design

• Product Feasibility Research & Analysis

• Mould Flow Analysis with DFM Report

• Product & Mould 2D/3D Design

Designing a great product and mould requires understanding every step of

the development process. Talent Mould has that understanding. In our

designing department, 5 design engineers with rich experience

in product design and mould design are always ready for

your project.

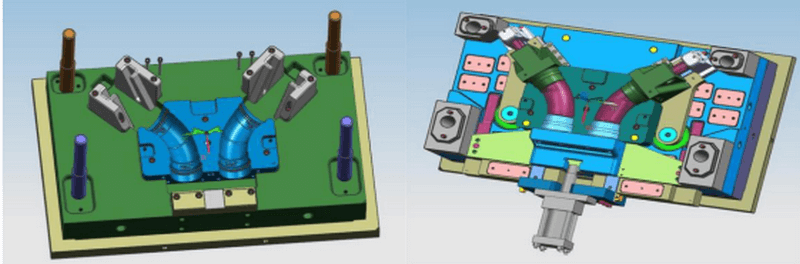

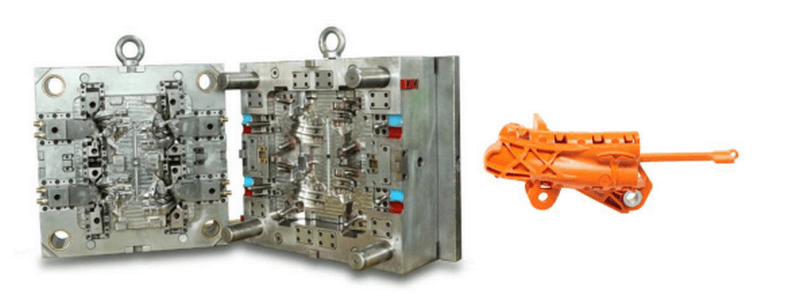

Tooling & Moulding

Mould technologies we are capable of:

• Multi-cavity (up to 128 cavities)

• Hot runner system (Mold Master, Incoe, Husky, Syventive, YUDO)

• Rotating cam sliders

• Collapsible cores

• 2-shot molds

• Stack molds

• Rapid prototype (SLA & SLS)

• Rapid prototype mould

• In-mould labeling/decoration

• mould maintenance & repair

With the wide range of capability, TTM can tailor the mold construction process to our customer’s needs. Our state-of-the-art facility allows us to complete molds in short lead time but with high quality.

Turnkey Service:

• Silicone mold design & manufacture

• Products surface treatment

• Shipment

• Products Assembly

Main Fields we serve:

• Automotive (Engine system, air venting system, audio/video system, internal & external accessories.)

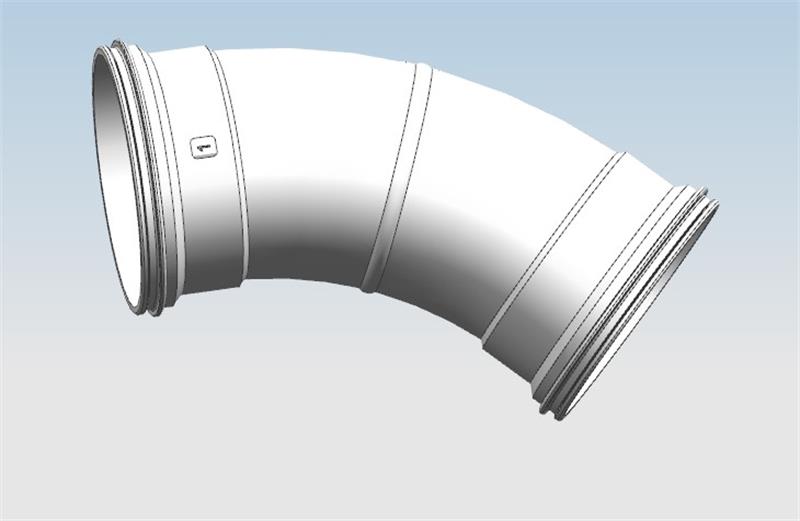

• Plumbing (PVC piping system)

• Medical (disposable medical devices, clinical devices, orthopedic devices)

• Industrial equipment

• Commercial Electronics

• Home Appliance

• Food and Cosmetic Packaging