Most of the die castings are made from non-ferrous metals,such as Zinc, Aluminium, Magnesium and so on.

Alumium alloy Die casting mold is an Alumium alloy casting process that by forcing molten aluminum under high pressure into a harden mold cavity blocks.

It depends on the type of the raw material of die casting parts, we could choose a hot or a cold chamber machine to use.

1.1730,P20,8407,2344,H13.

Heat treatment of steel :Harden,Nitrition,Quench

Alumium Alloy part Material: ADC12(which is common material), AlSi12,ADC10,A380,A360,A413

Magnesium Alloy part Material: AZ91D,AM60B,AM50A,AS41B

Surface treatment can be made by machining,polishing,oxidation or painting.

The Process

The die casting die or mold is a closed vessel into which molten metal is injected under high pressure and temperature, then rapidly cooled until the solidified part is sufficiently rigid to permit ejection from the mold.

Tooling

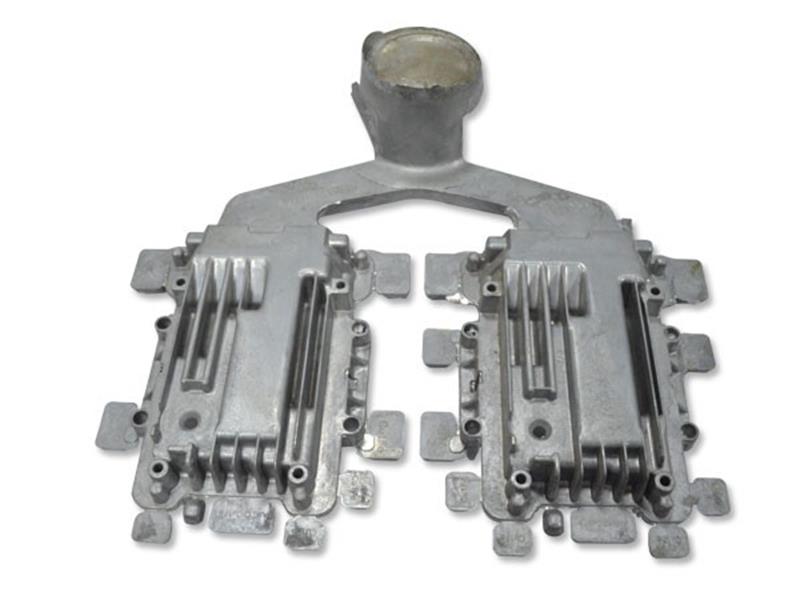

Dies, or die casting tooling, are made of alloy tool steels in at least two sections, the fixed half (cover half) and the moving half (ejector die half), to permit removal of the castings. The dies also may have moveable slides, cores or other sections to produce holes, threads and other desired shapes in the casting.

Making the Mold

The two die halves run in a die casting machine that is operated at the required temperatures and pressures to produce a quality part to net-shape or near-net-shape customer specifications. When the die casting machine closes, the two die halves are locked and held together by the machine’s pressure. The surface where the ejector and the fixed halves of the die meet and lock is referred to as the “die parting line”. The total projected surface area of the part being cast, measured at the die parting line, governs the clamping force of the machine.

For longevity of operation in this environment the die casting die must be built from high-quality tool steel of exacting specifications, heat-treated to the required hardness and structure ( Guidelines from NADCA exist for this reason), with dimensions of the die and cavity machined to exacting specifications.

The customer’s product design requirements directly affect the size, type, features, and cost of the required tooling. The items involved in the tooling decision include the number of cavities, number of core or slide requirements, weight of the die, machining, finish requirements, polishing and plating to name just a few.