Model Number: TE09-201

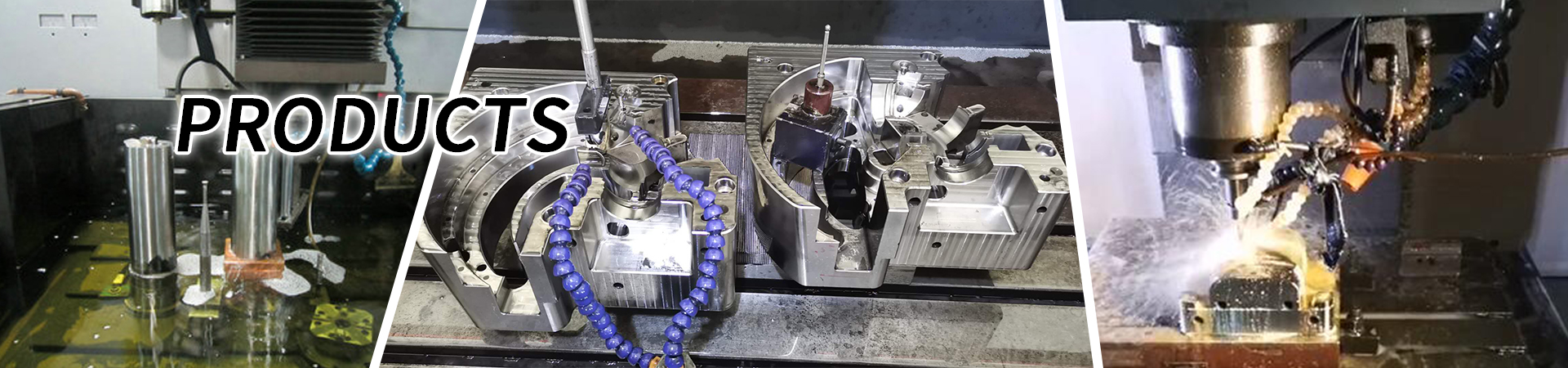

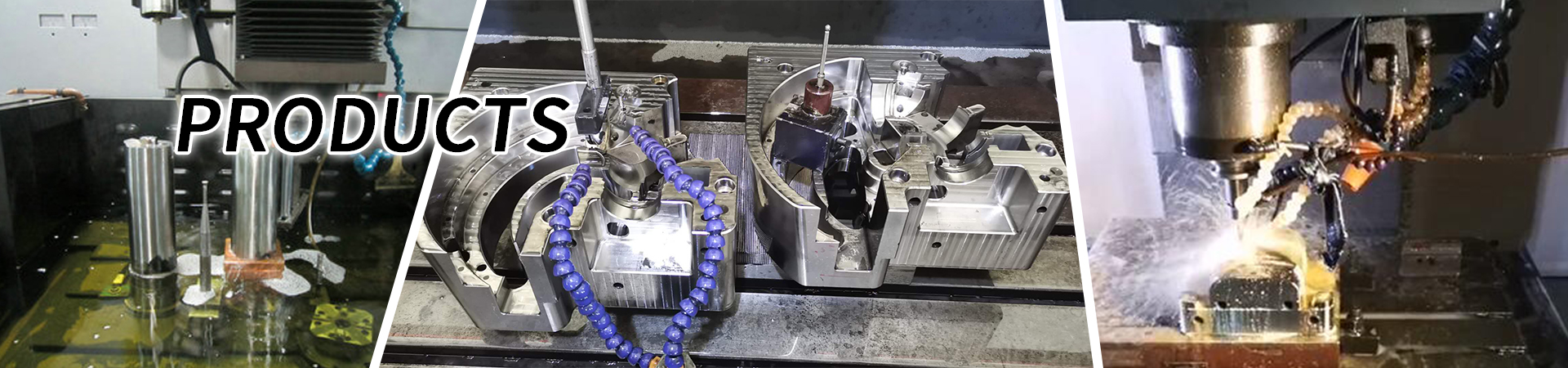

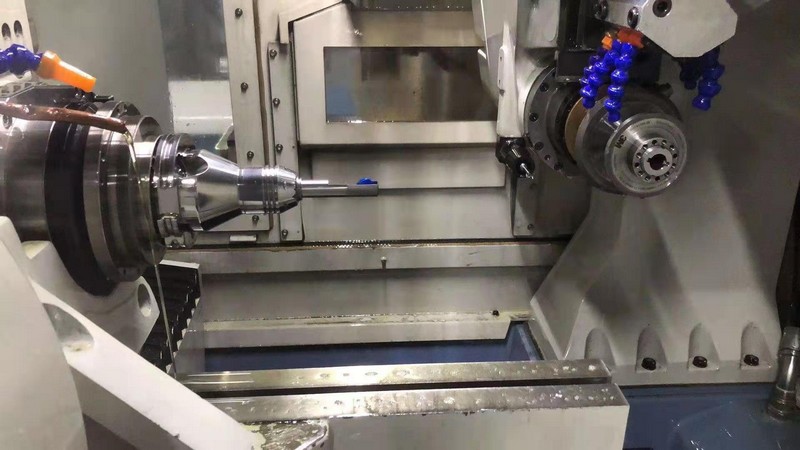

Product Name: Aluminum Machined Parts

Brand Name: TTM

Material: Aluminum 6061

Process: CNC milling, turning, machining, EDM, laser cutting

Surface Treatment: Anodizing + sand blasting

Lead Time: 5~15days depends on the complexity and the quantity of the products.

| Product Name | Precision Machined Parts |

| Brand | OEM |

| Machined Material | Alloy Steel, Stainless Steel, Carbon Steel, Aluminum, Brass, Copper, Ceramic, Plastic, etc. |

| Surface Treatment | High polishing, passivating, anodized, heat treatment,sandblasting, brushing, chrome, powder coating, painting, laser engraving, silk screen, etc. |

| Process Type | CNC milling, turning, machining, laser cutting, grinding, broaching, drilling, etching, wire EDM |

| Drawing Format | IGS, STP, DXF, DWG, PDF, Pro/E, UG |

| Test Equipment | Measurement instrument, projector, CMM, altimeter, thread gages, calipers, pin gauge, etc. |

| Certification | ISO9001:2015 |

| Lead Time | 5~15days depends on the complexity and the quantity of the products |

We Supply rapid prototyping, 3D printing and precision machining for small/ large batch production of mechanical parts, engineering parts, plastic parts and hardware spare parts.

2D: Auto-CAD 2014, Edrawing, etc

3D: Pro/Engineer, UG 10.0, Solidworks, Catia, Moldflow 2014, etc

CNC Programming: MasterCAM, UG 8.0, etc

We can readily receive small and large CAD files in a variety of formats, like:

2D: dwg, dxf, edrw, pdf, etc

3D: step, igs, x_t, stp, prt, Sldprt, etc

We guarantee your idea will be taken step-by-step through the process, from CAD design through production and assembly.

Appointment of a dedicated project manager to each mould-project

Project manager having the following tasks / responsibilities:

project planning, reporting, change management and customer-interface organize and manage design & production reviews, try-outs with delivery of samples , final approval and mould delivery.

Progress and status reports are issued each week including photos.

Communication is done in English with marketing dept.

To be always able to deliver high quality mould and precision products to our customers, the highest level of quality assurance is essential for us.

This starts with the contract review over the entire project cycle and ends with the shipping process.

We have therefore implemented a Quality Management System according to ISO 9001:2015 allowing for continuous improvement of our processes.