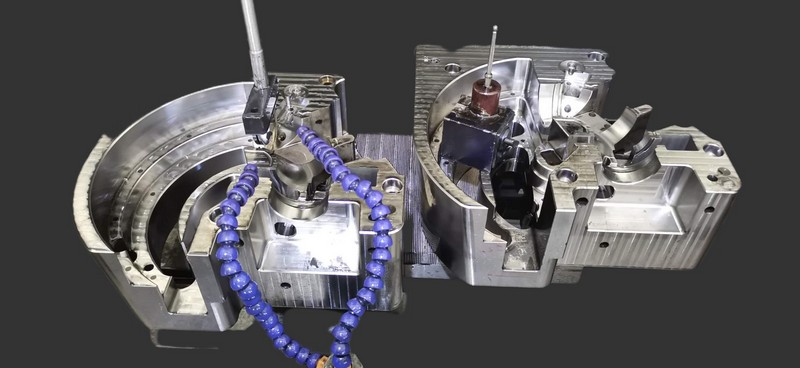

Model Number: TE05-021

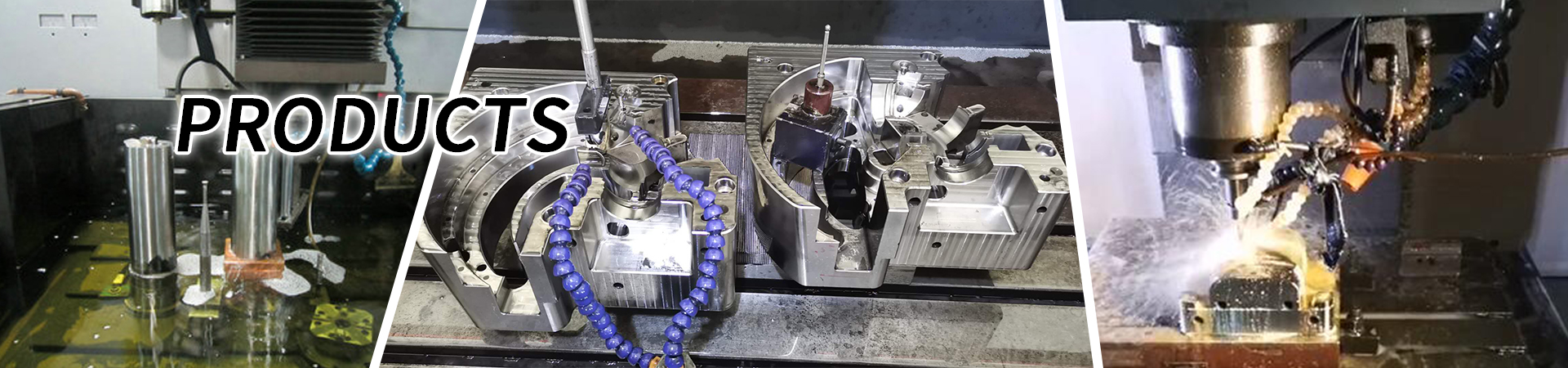

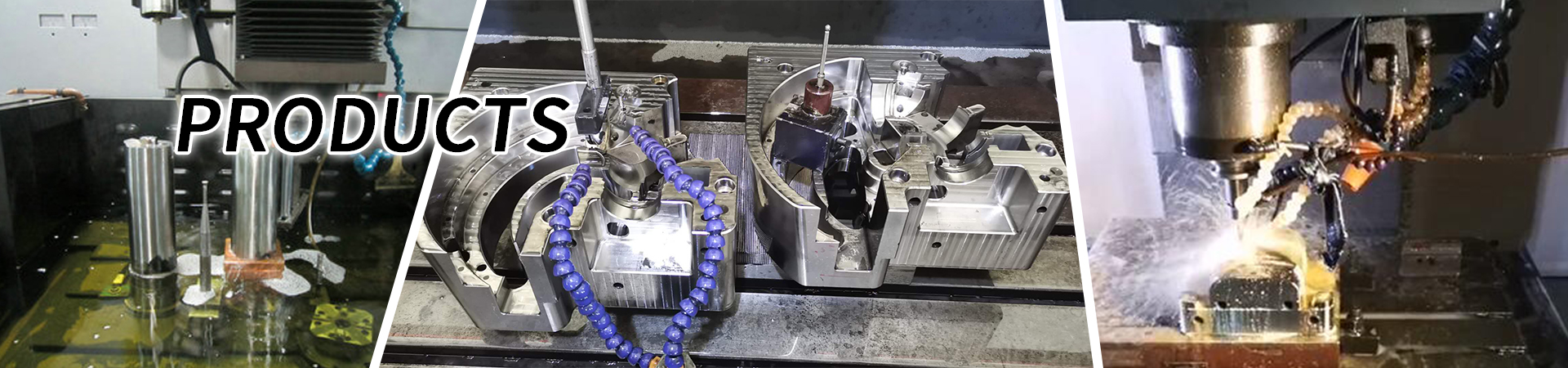

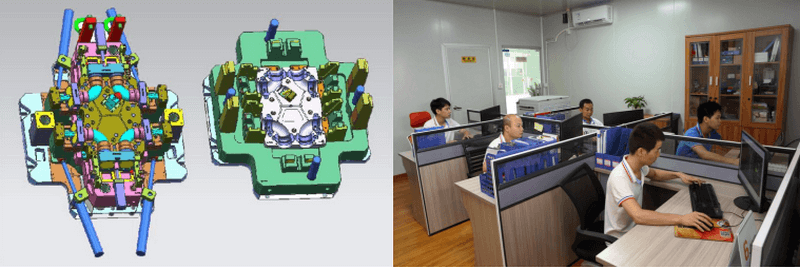

Product Name: Auto Pipe Mould

Brand Name: TTM

Mould Type: Plastic Injection Mould

Mould Base: P20

Mould Cavity and Core: H13

Mould Cavity: 2+2

Injection: Cold Runner

Mould Life: 500,000 shots

Mould Size: 1200*1000*800 mm

Mould Weight: 6200 kgs

Plastic Parts Material: PP + 30%GF

Surface: Polish #400

| Brand | TTM |

| Mould Base | LKM, HASCO, DME, C50 standard mould base |

| Mould Material | H13, 1.2344, 1.2738, P20, 45#, etc., according to customers’ requirement. |

| Mould Standard | HASCO, DME, MISUMI, LKM, etc. |

| Product Material | ABS, PP, PC, PA, PA66, POM, etc. |

| Runner | Cold/Hot Runner |

| Gate Type | Side gate, sub gate, pin point gate, edge gate, etc. |

| Mould Size(min) | 150*150mm |

| Mould Size(max) | 1600*1200mm |

| Mould Weight | 50~15,000 kg |

| Injection Machine Type | 80~1500ton |

| Certification | ISO9001:2015 |

| Lead Time | 3~6weeks according to the product |

For the Auto pipe mold, it’s very big with high quality and precision requirement. From purchase the mold steel to mold fitting, we spent 50 day to produce. And we made 2 times trial shot until our customer approved the samples. This mold makes us very fulfilled and our technology is constantly improving as well.

Established in 2008, Talent Technology Mould Co., Ltd is specialized in plastic mould, alloy mould design and manufactue, bulk production for plastic parts and alloy parts, also supply turnkey service for rapid prototyping, precision machining, surface treatment and assembly. Our products are mainly used for automotive, medical device, mechanical engineering, equipment industry, household and so on.

Production Scope:

* Plastic injection mold with tolerances up to ±0.02mm.

* 2K/Dual-component molds

* Over Molding

* Gear Mould

* Die-Casting Mould

* Injection Molding

* Precision Machining

Turnkey Service:

* Silicone Molds

* Rapid-Prototyping & 3D Printing

* Surface Treatment

* Product Assembly

It will take about 2-5 days for us to make 3D mould design , it will depend on how many sets of molds and how complexity of the mold.

If customer confirmed our 3D design, we ‘ll make 2D drawing with the BOM for our customer to check all of components steel material specification .

If the part is complexity , or the filling speed is hard to confirm, we could offer the mold analysis report to customer .

Our project manager having the following tasks / responsibilities:

● Project planning, reporting, change management and customer-interface organize and manage design & production reviews, try-outs with delivery of samples , final approval and mould delivery.

● Progress and status reports are issued each week including photos.

● Communication is done in English with marketing dept.

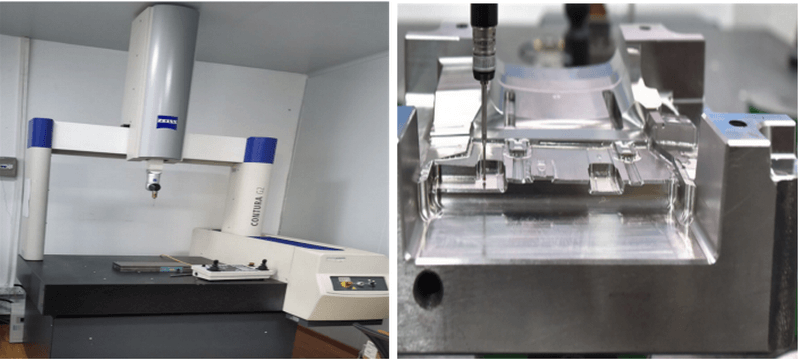

To be always able to deliver high quality mould an plastic products to our customers, the highest level of quality assurance is essential for us .

This starts with the contract review over the entire project cycle and ends with the shipping process.

We have therefore implemented a Quality Management System according to ISO 9001:2015 allowing for continuous improvement of our processes.