Product Basic Information:

Product Name: Silicon rubber keypads

Model Number: TD21

Brand Name: OEM

Material: TPE, TPU

Color/Surface finish: Custom Color

Size: According to your drawings

Packaging Details: Poly bag+export carton or according to customers’ requirements

Port: Shenzhen, China

Lead time: 4 weeks

![]()

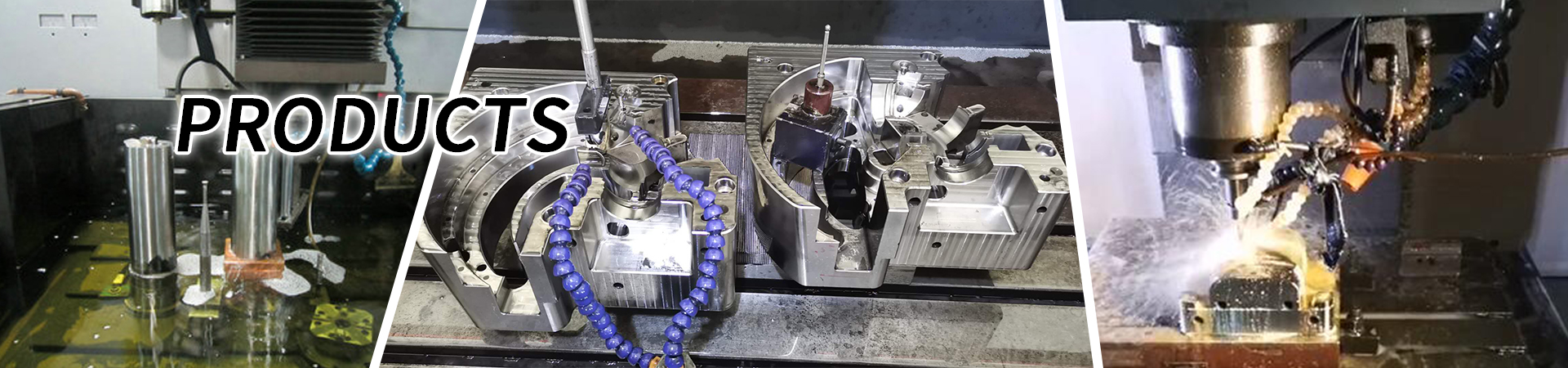

1.TTM Can offer total solutions to customer’s idea with in-house production/assembly and outsourcing program.

2.TTM adopts lean practices and process optimization including the use of technology to achieve“best costs”.

3.Strict quality management is enforced at all stages.

4.In-house Mould design and manufacturing.

5.Good experience on developing designs according to customer’s requirements.

![]()

Respect is the basic attitude TTM company and our individual workers have.

We work and cooperate on equal basis, respecting and expecting to be respected.

Responsibility is the commitment and guidance we have, to our valued customers, to the company, to the society.

Return is the virtue we insist and carry forward.

For any parties or individuals who supported us, we always keep gratitude in heart and return with greater support.

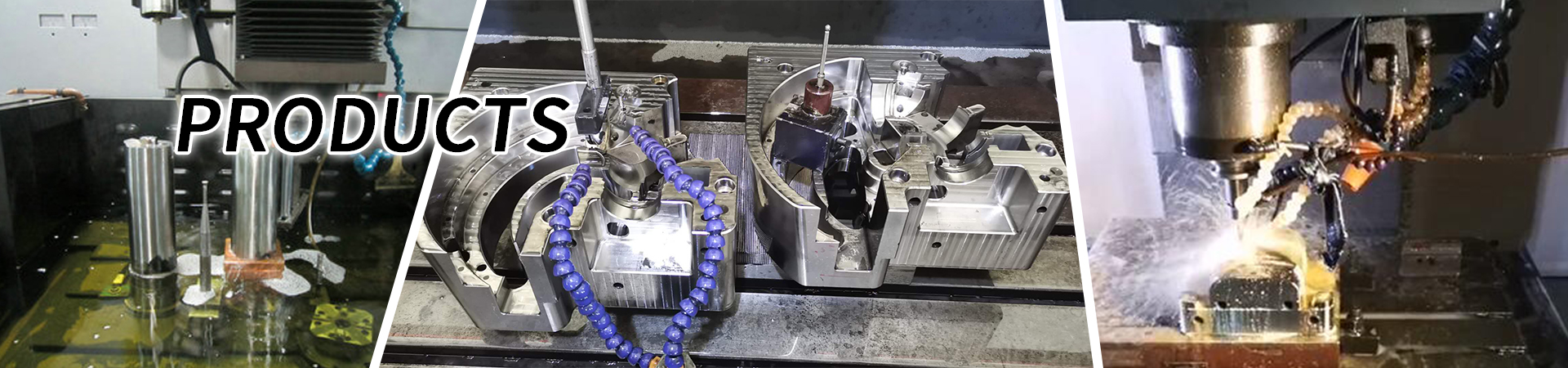

A project engineer will be assigned to follow your order right through the design to sampling and tool shipment. The engineer will act as your representative to make sure the technical and quality standard are fully implemented, and do not worry they speak and understand English very well.

The weekly progress report and online tracking project management ensure the process is running on schedule to avoid rushing in last minute.

Following final design approval and tool manufacture, samples are submitted with a fully detailed inspection report and setting parameter.

![]()

Talent now is relocated in a 6000 sq meters factory with 100 staff in which includes 8 English-speaking project engineers, 12 design engineers and 50 mould makers. Consistent investment from August 2013 on new and better machines has enhanced our capability and will greatly increase our advantages in the market.

![]()