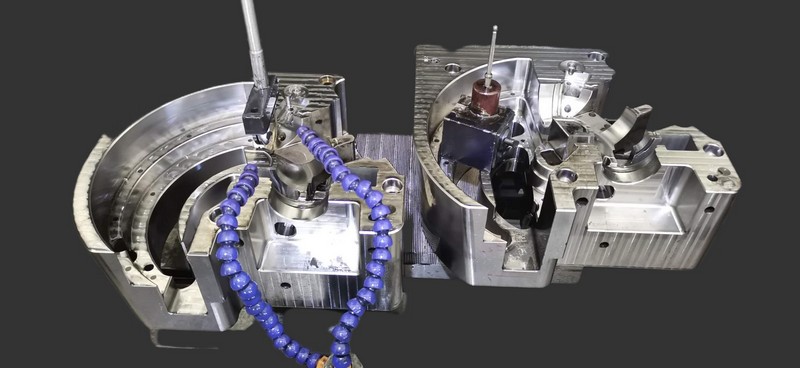

Product Basic Information:

Product Name: Plastic Injection Water filter Parts

Model Number: TD09

Brand Name: OEM

Material: PP,PE,TPU,PC, ABS, NYLON…

Application: Home Appliance

Color: Custom Color

Size: According to your drawings

Packaging Details: Poly bag+export carton or according to customers’ requirements

Port: Shenzhen, China

Lead time: 4 weeks

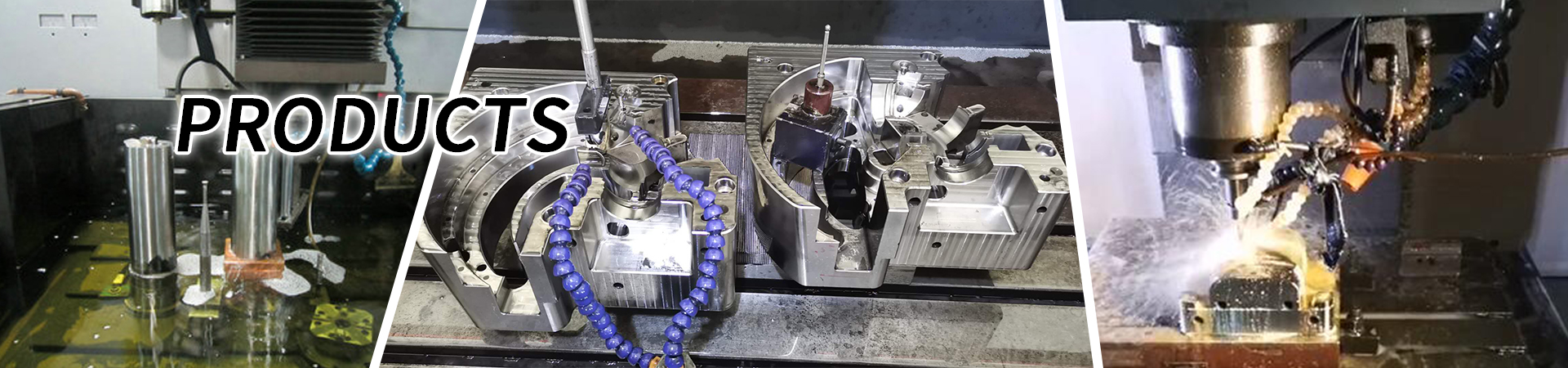

Talent now is relocated in a 6000 sq meters factory with 100 staff in which includes 8 English-speaking project engineers, 12 design engineers and 50 mould makers. Consistent investment from August 2013 on new and better machines has enhanced our capability and will greatly increase our advantages in the market.

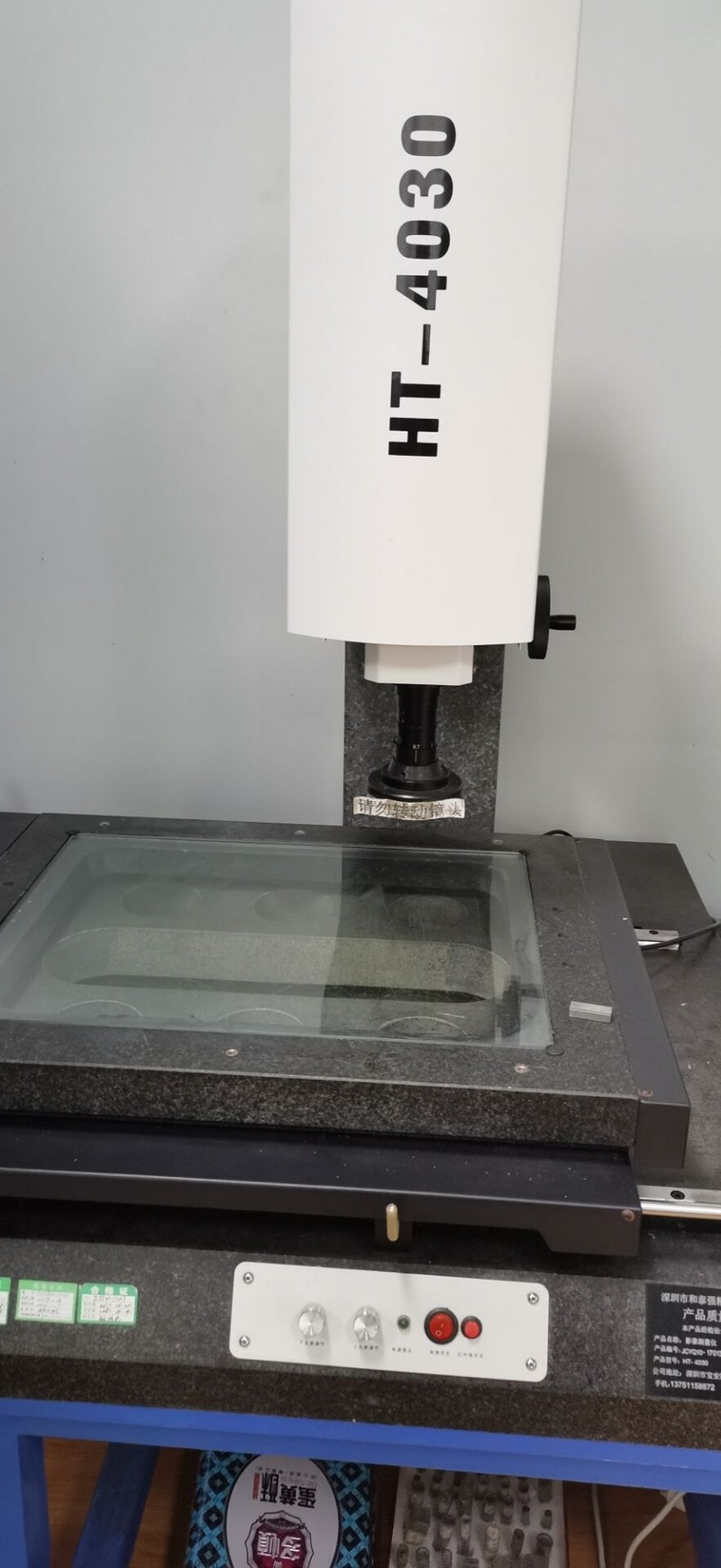

To be always able to deliver high quality mould an plastic products to our customers, the highest level of quality assurance is essential for us .

This starts with the contract review over the entire project cycle and ends with the shipping process.

We have therefore implemented a Quality Management System according to ISO 9001:2015 allowing for continuous improvement of our processes.

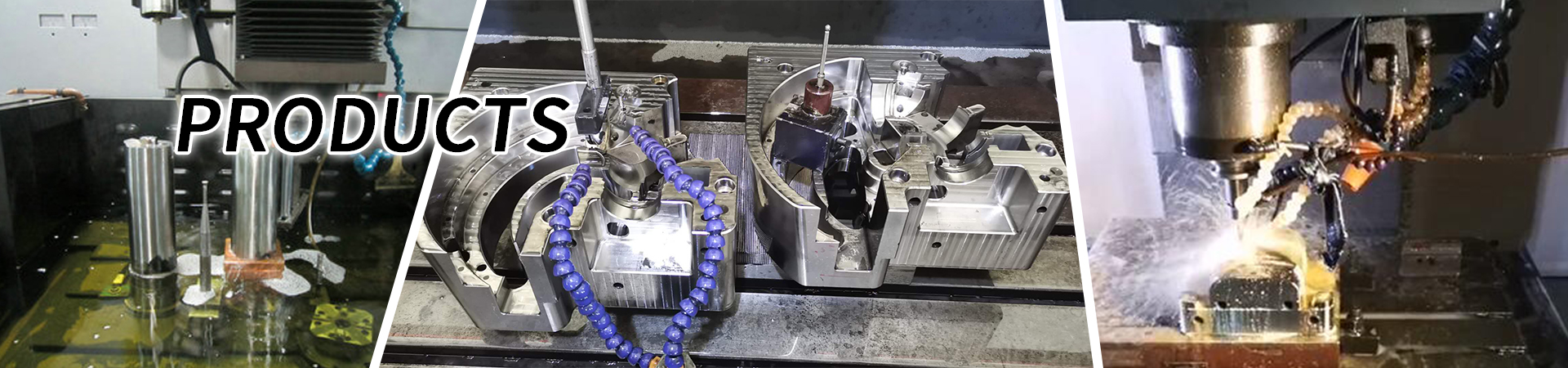

Product Design

Product Feasibility Research & Analysis

Mould Flow Analysis with DFM Report

Product & Mould 2D/3D Design

Designing a great product and mould requires understanding every step of

the development process. Talent Mould has that understanding. In our

designing department, 12 design engineers with rich experience

in product design and mould design are always ready for

your project.

Latest mould design software we are now using:

2D: Auto-CAD 2014, Edrawing, etc

3D: Pro/Engineer, Unigraphics 9.0, Solidworks, Catia, Moldflow 2012, etc

CNC Programming: MasterCAM, Unigraphics 8.0, etc

We can readily receive small and large CAD files in a variety of formats, like:

2D: dwg, dxf, edrw, pdf, etc

3D: step, igs, x_t, prt, Sldprt, etc

We guarantee your idea will be taken step-by-step through the process, from CAD design through production and assembly.