Product Basic Information:

Product Name: Plastic Electrical tanks

Model Number: TD05

Brand Name: OEM

Material: PP,PE,TPU,PC, ABS, NYLON…

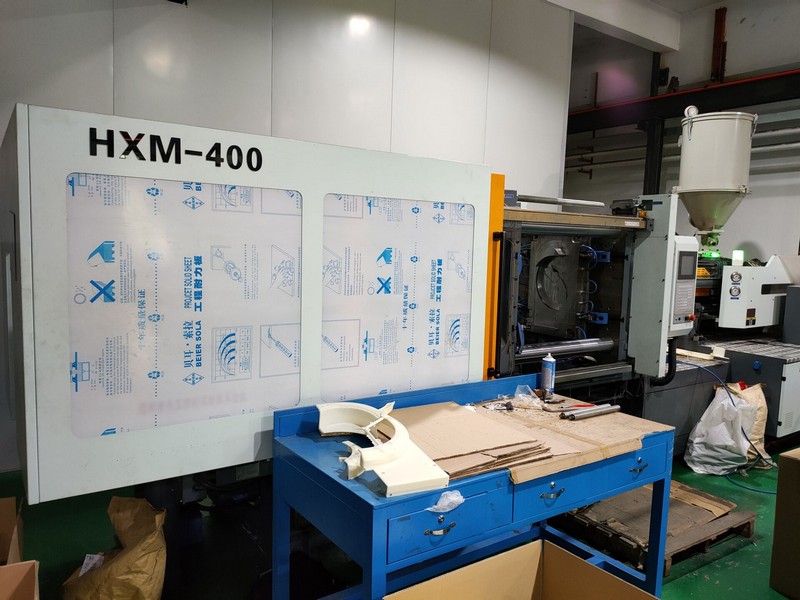

Technology: Mould Injection

Color/Surface finish: Customizable

Size: According to your drawings

Packaging Details: Poly bag, pearl-cotton package, export carton according to customers’ requirements

Port: Shenzhen, China

Lead time: 4 weeks

Deliver by express, air, sea, according to customers’ requirement.

TTM Can offer total solutions to customer’s idea with in-house production/assembly and outsourcing program.

TTM adopts lean practices and process optimization including the use of technology to achieve“best costs”.

Strict quality management is enforced at all stages.

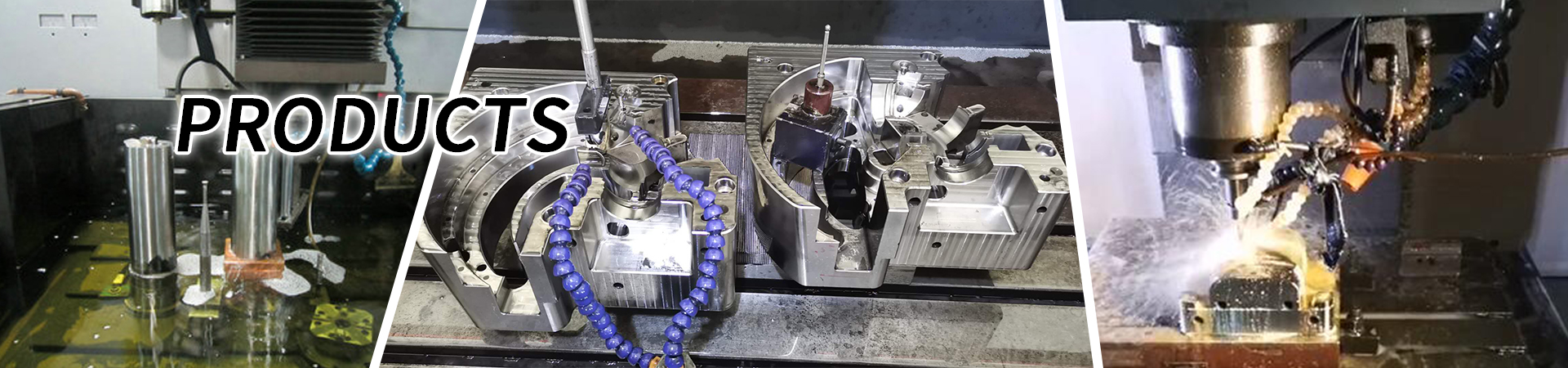

In-house Mould design and manufacturing.

Good experience on developing designs according to customer’s requirements.

Talent Technology Mould Co., Ltd. is engaged in providing “high-quality” and

“delivery on-time” services for customers, now it already has become the first-ranking manufacturer in high-precision and complicated injection mould production.

TTM has the tools and talent to support your product development process. TTM is ready to assist in your design process with a dedicated staff of engineers, with years of tooling and plastic injection mold experience. We address potential manufacturing issues before the product enters into production. We can also help you select the raw material to maximize product performance. Our early involvement in your product development not only eliminates headache, it saves both time and money.

TTM owns a quality control system, the ISO9001:2008. We focus on customer demands and regard quality as the foundation for our long-term stable development, setting up independent quality departments for mould manufacturing and injection molding. We sincerely hope we can cooperate with you to reach the goal of win-win cooperation..

Welcome to visit our factory!

Talent now is relocated in a 6000 sq meters factory with 100 staff in which includes 8 English-speaking project engineers, 12 design engineers and 50 mould makers. Consistent investment from August 2013 on new and better machines has enhanced our capability and will greatly increase our advantages in the market.